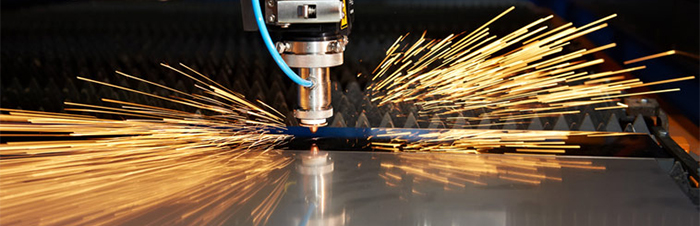

Laser processing

Laser metal processing is carried out using a laser system TRUMATIK6000L-1300 in “Beltra” company. TRUMATIK6000L-1300 provides laser cutting, cutting and shaping in one machine, complete machining with a single setup, reducing the time of products manufacturing.

Also, the device performs the following processing operations of a material such as steel:

- cutting internal and external contours without scale;

- cutting sections detail subjected morphogenesis;

- cutting metal;

- carving individual contour elements in one move;

- forming elements received a few passes of the tool;

- thread formation;

- marking by laser engraving and punching;

- it possible to produce large and small series parts from different materials cost-efficient and in a short period of time.

TRUMATIK6000L-1300 provides high-speed laser processing, high accuracy due to the rigid structure of modern drives and measuring systems.

Features of laser cutting:

- No mechanical impact on the material being processed.

- A quick and cheap way of sheet metal compared to mechanical, without loss of quality.

- The cost of virtually no effect on the volume of the party.

Features of the complex:

- Working area 1500 x 3000 mm.

- Cutting Metal: Steel - up to 10 mm, stainless steel - up to 2 millimeters and aluminum alloys - up to 3 millimeters.

- Cutting speed up to 12 m \ min.

Accuracy: The minimum size of a programmable motion - 0.01 millimeter. Positioning accuracy of + \ - 0.1 millimeters.

Maximum work piece weight is 200 kilograms.